In the manufacturing industry small defects can lead to product recalls, delays, and broken customer trust. Traditionally, inspection techniques were time-consuming, prone to error as they were done manually by humans to detect structured product defects. However, with computer vision AI technology, manufacturers now can inspect products at lightning speed, identifying defects precisely that humans can’t match.

There might be numerous times when a defect could have slipped through unnoticed on your production line—and you couldn’t save them even though you might have caught them all. Computer vision as an optical defect detection solves this problem. It is changing the game in defect detection.

In this blog, we will explore how computer vision AI for defect detection can help manufacturers and business owners by redefining quality control and setting new standards for precision.

What is computer vision AI for defect detection in manufacturing?

Computer vision for defect detection in manufacturing is the process of inspecting the quality of products with the help of visual AI technology. This technology uses deep neural networks, such as deep convolutional networks for tasks like crack detection, object detection, and non-destructive testing. It analyzes images and videos of products on the product line identifying defects like missing parts and scratches thus improving quality control.

AI can identify patterns and issues which can be easily ignored by human eyes. Computer vision as an optical defect detection technology helps businesses and manufacturers by significantly improving defect detection in products by reducing scraps, and delays, speeding up the entire process. This technology seems highly promising for industries and processes that require high accuracy in defect detection.

Drive accuracy, speed, and compliance with tailored machine vision solutions. Our experts align cutting-edge technology with your unique operational needs, streamlining workflows and reducing errors. Elevate your logistics performance today.

Benefits of computer vision AI for defect detection

Integrating AI for defect detection in the manufacturing process can offer numerous benefits.

1. Cost saving

Identifying defects in the initial stage of production can reduce waste and rework costs. Moreover, predictive maintenance can reduce the cost of equipment failure. Improved product quality reduces the number of warranty claims, helping organizations to save costs on customer services.

2. Improved accuracy

AI-driven visual inspection analyzes large sets of data and finds defects with full precision. By identifying defects in the early-stage, manufacturers can prevent them from progressing to the next stage, eliminating waste and rework. Moreover, computer vision can provide real-time feedback on product quality, providing opportunities to make immediate adjustments. This accuracy helps manufacturers to ensure products meet strict quality standards and regulatory requirements.

3. Enhanced safety and security

Computer vision AI identifies possible safety hazards in equipment or production processes, helping to predict and prevent accidents on time, and ensuring a safer working environment. It also reduces strains on human inspectors, helping them to focus on more complex tasks. Thus, streamlining manufacturing operations improves production.

4. Increased efficiency

AI-powered computer vision can function constantly without fatigue, unlike human inspectors. This offers real-time inspection and eliminates production delays caused by human judgments. Computer vision can process images and videos at high-speed providing quick inspection and faster turnaround. Moreover, identifying potential issues in the early-stage, AI can prevent downtime and equipment failure.

5. Scalability

AI can analyze large volumes of data, scale detection processes as per the requirements and adapt to different manufacturing environments making them suitable for a wide range of industries and production processes. Computer vision uses data analytics to provide insights for continuous improvement.

Suggested: Top 9 applications of computer vision in manufacturing

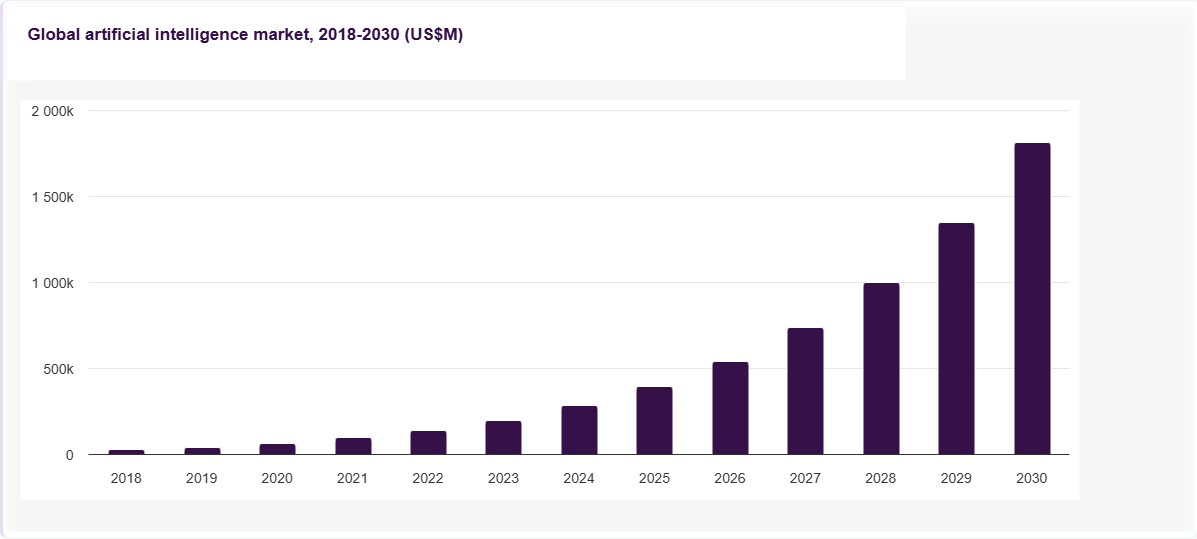

Global artificial intelligence in manufacturing market highlights

The following data by Grand View Research and MarketsandMarkets showcases the growth of AI and computer vision market across the globe.

Source: grandviewresearch

- The AI in the computer vision market is expected to reach USD 63.48 billion by 2030, up from USD 23.42 billion in 2025, reflecting a CAGR of 22.1%.

- The global artificial intelligence in manufacturing market size was estimated at USD 5.32 billion in 2024 and is projected to grow at a CAGR of 46.5% from 2025 to 2030.

- The global artificial intelligence in the manufacturing market generated a revenue of USD 5,321.5 million in 2024 and is expected to reach USD 47,881.3 million by 2030.

How does AI defect detection work in manufacturing?

AI defect detection system in manufacturing inspects quality of products. Here is how the process unfolds:

1. Capturing image

AI starts the process by collecting data which it utilizes for training purposes. In manufacturing, data collection involves collecting real-time images of each product as the product is produced and passes through the production line. This helps AI systems learn what is a good product and identify deviations in defective products.

2. Pre-analysis of image

Once the images are collected, they need to be pre-analyzed and marked for better input quality as they directly impact the model performance. The data cleaning process eliminates inconsistency and irrelevant data that affects AI tool’s result. Image pre-analysis process involves labeling images or videos to identify if the product is defective, if so, the defective part is highlighted.

3. Pattern recognition

AI processes thousands of data per second which is faster than a human eye can inspect. The system uses various techniques to extract notable aspects from the pre-analyzed images including identifying new patterns, textures, and dimensions.

4. Defect detection

Using deep learning and machine learning models, AI compares the extracted features in the image with the pre-defined patterns of the non-defective times. It identifies defects and categorizes them into different types like cracks, scratches, misalignments, discoloration, etc. Difference from the pre-defined patterns is marked as defect in the products. AI models analyze products from multiple angles for deeper understanding.

5. Action

The system automatically sorts out the defective products and sends alerts via dashboards, IoT devices and mobile apps for detailed inspection. AI integrates robotic arm or belt sorting system to automatically remove defective items. Moreover, AI assigns severity scores, and minor changes can be corrected through rework while major defects trigger production rejects. AI is synched with ERP systems to log defects and analyze trends and suggest process optimization.

Suggested: Top 8 computer vision trends for 2025 and beyond

Use cases of the computer vision AI for defect detection

1. Quality inspection

Use case: Computer AI vision identifies adulteration, contamination, and packaging defects in production processes. Food and manufacturing must meet strict regulatory standards to ensure products are free from defects. Even minor inconsistency can lead to safety issues.

Application: AI detects broken, contaminated food and medicines in production lines, restricting unsafe products from reaching the consumers. It alerts manufacturers in real-time when irregularities are found, preventing defective products from being shipped.

Benefits

- Reduces recalls and waste

- Ensures compliance with safety regulation

- Maintains consumer trust for good quality

2. Assembly verification

Use case: Computer AI vision ensures all components are correctly assembled and properly aligned.

Application: AI inspects machinery and circuit boards to verify capacitors, receptors, and microchips are properly placed reducing the defect. AI models compare the pre-defined design specification with circuit boards produced to ensure all the components are properly aligned and are sturdy.

Benefits

- Prevents misalignment and identifies the missing parts

- Enhances efficiency by reducing first-pass errors

- Reduces costly rework and recalls

3. Object defect defection

Use case: Computer vision identifies discoloration, cracks, dents, and scratches in finished products and raw materials. For industries like automotive, flawless vehicles are crucial to maintain their brand reputation. Traditional manual inspection can often miss minor surface defects leading to costly rework.

Application: AI-powered vision scans raw materials and products to identify small anomalies that can be missed through the human eye and alert quality control team, reducing the chances of defective products reaching end-customers.

Benefits

- Speeds up the process of defect detection

- Ensures consistency in product quality

- Reduces errors that can be caused by human inspection

4. Packaging and labeling

Use case: Computer vision AI ensures packages and barcodes are correctly labeled and properly sealed. Packaging and labeling errors can lead to costly recalls, regulatory issues, and damage to brand reputation. Even minor errors—such as incorrect expiration dates, misprinted labels, or damaged packaging—can create significant business risks.

Application: AI vision scans product packaging for mislabeling, incorrect expiration dates, printing errors, and tampering. High-speed cameras analyze package dimensions and structure, flagging deformities or incorrectly sealed products. AI ensures tamper-proof packaging compliance, reducing the risk of compromised goods reaching customers.

Benefits

- Improves supply chain tracking

- Prevents miss-labeling and regulatory non-compliance

- Reduces customer dissatisfaction

From waste to precision: The future of flawless manufacturing starts now!

Adopting computer vision AI for defect inspection has numerous benefits for manufacturing companies through the delivery of intelligent and automated solutions. This improves the efficiency, accuracy, and cost-effectiveness of quality assurance processes. As AI becomes more integrated and accessible to manufacturing processes, it will help industries to grow, bringing new opportunities for growth and innovation.

Contact us to learn how our computer vision AI solutions can enhance your business efficiency.

Need Help ?

We are here for you