Customer Background

The client is a leading retail company that features a diverse selection of consumer electronics, home appliances, personal gadgets, fashion items, accessories, and beauty products. With over 250 physical stores across the United States and a popular online store, they offer electronic products, clothing, footwear, jewelry, handbags, and personal care products as well. They are well known for their wide product range and competitive pricing; the company has established a loyal customer base over the past two decades of operation.

Challenges

The retail chain faced multiple operational hurdles:

- Miscalculated demand : They struggled with accurately predicting customer demand. This led to frequent cases of overstocking and understocking, hence missing sales opportunities and increasing holding costs.

- Restricted insight: The company lacked real-time visibility into any critical operational data, like inventory levels, supplier performance, and order tracking status. This limited their potential to respond quickly to supply chain disruptions, market changes and customer demands.

- Non-automated supply chain processes: Manual processes like managing inventory, processing orders, and coordinating with suppliers often created errors, inaccuracies, and delays. This reduced supply chain effectiveness as well as increased operational costs.

Solutions

Our team of experts connected with the client’s operations team. We conducted multiple sessions, understanding and evaluating the client’s operational processes. After a thorough assessment of their business processes, identifying key pain points and areas for improvement, we suggested implementing Microsoft Power BI to address their challenges.

Implementation of Power BI

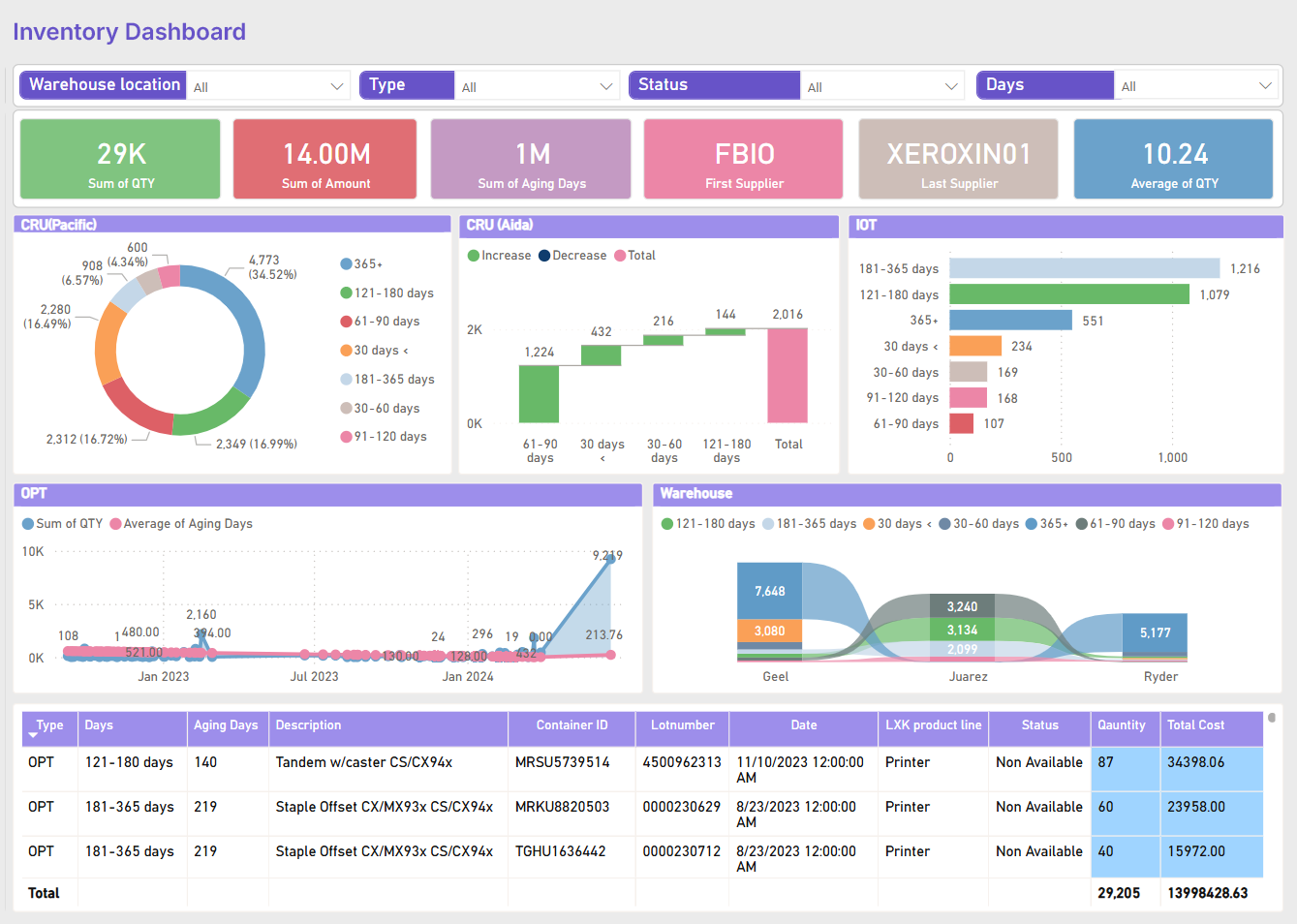

- Developed a centralized Power BI dashboard integrating real-time data streams from sales, inventory, suppliers, and logistics.

- Built advanced predictive models to analyze historical data for accurate demand forecasting.

- Automated reporting processes to provide actionable insights into market trends, inventory health, and supplier performance.

Process automation

- Introduced automation for inventory updates, order tracking, and demand planning workflows, drastically reducing manual errors.

- Enabled automated alerts for critical stock thresholds and impending delivery delays, ensuring timely corrective actions.

- Streamlined supplier communications, making procurement cycles faster and more efficient.

Real-time inventory and supply chain management

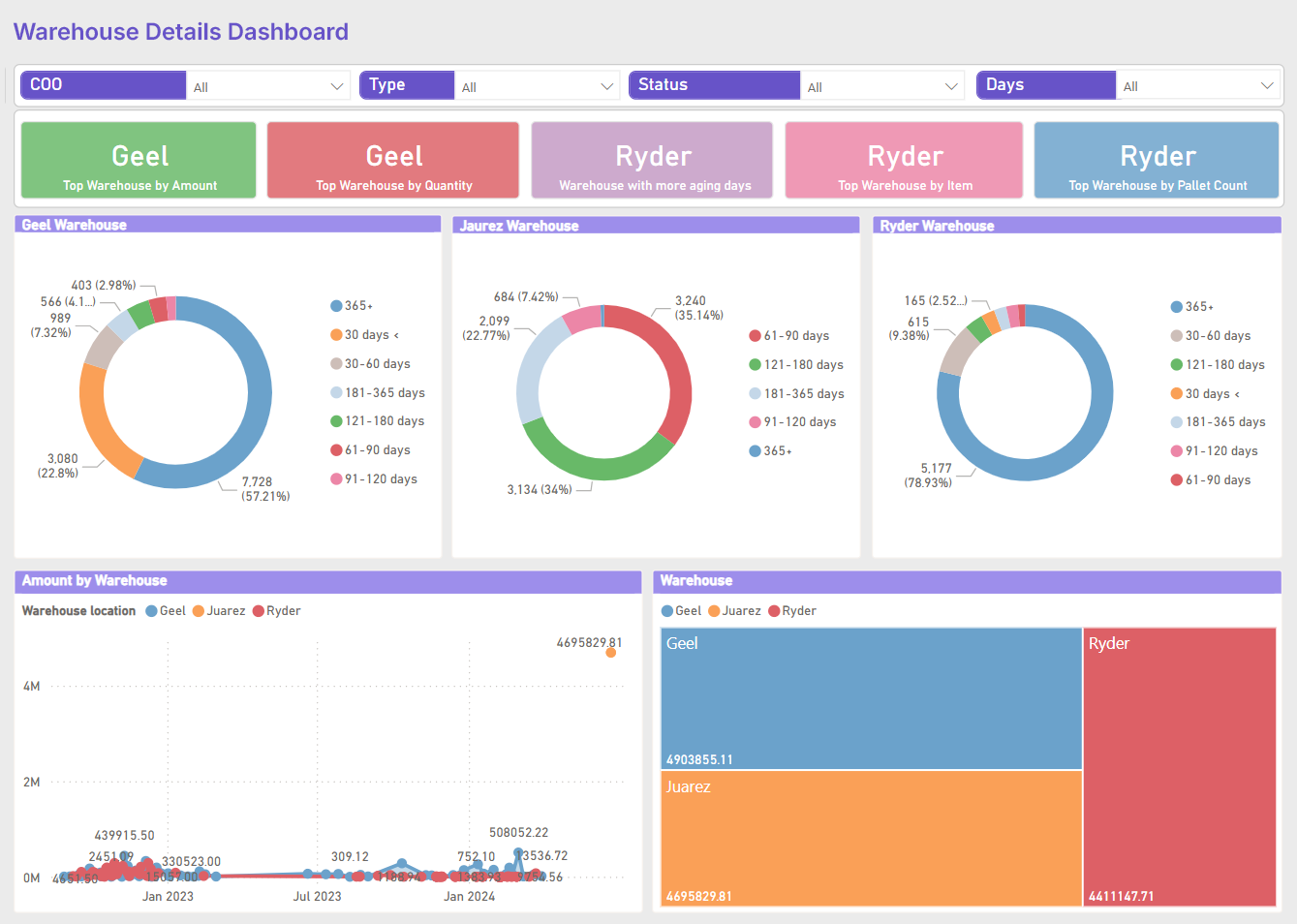

- Integrated Power BI with inventory databases and supplier systems to enable real-time monitoring of supply chain performance metrics, including inventory levels, lead times, and order tracking status.

- Enabled dynamic reallocation of inventory across stores to optimize stock availability and reduce excess holding costs.

- Monitored supplier compliance with agreed-upon timelines, ensuring seamless supply chain operations.

Enhanced supplier collaboration

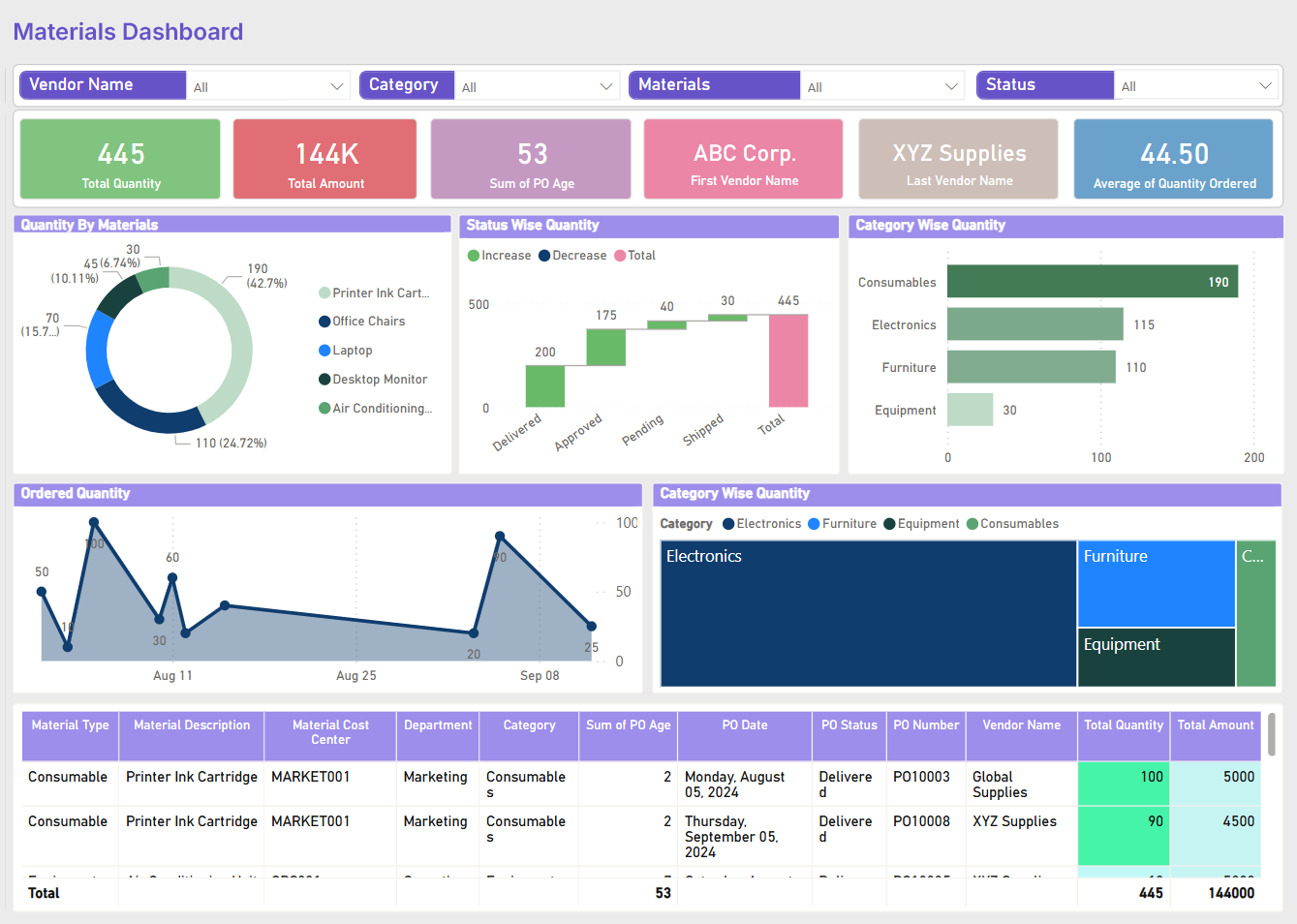

- Integrated supplier data into Power BI to develop a performance monitoring dashboard.

- Assessed key metrics such as delivery timelines, product quality, and order fulfillment rates.

- Established stronger supplier relationships, negotiated better terms, and resolved issues related to delays or inconsistencies using useful insights.

Training and change management

- Conducted workshops and training sessions for employees to ensure smooth adoption of Power BI tools and automated workflows.

- Implemented a continuous feedback mechanism to refine data models and improve operational processes based on real-world performance.

- 40%

improvement in demand prediction

- 30%

reduction in operational costs

- 50%

acceleration in inventory reallocation

Inventory Dashboard

Materials Dashboard

Warehouse Detail Dashboard

-

Industry

Retail

-

Technologies / Platforms / Frameworks

Power BI

-

Benefits

- Improved demand accuracy : Precise demand forecasting minimized overstocking and stockouts significantly improving inventory turnover.

- Real-time decision-making : With real-time access to data they efficiently ensured that shelves were stocked with in-demand products, eliminating obsolete inventory.

- Operational efficiency : Automated reporting and streamlined workflows led to a significant drop in processing times. This allowed the team to focus on strategic initiatives in place of dealing with operational issues.

- Cost savings : Optimized inventory management and reduced wastage lowered operational costs significantly.

- Customer satisfaction : Enhanced inventory availability and faster turnaround times improved customer satisfaction ratings, translating into higher customer retention and increased sales.

- Scalable framework : The scalable nature of Power BI allowed the company to expand its solution to other operational areas, such as marketing and supply chain optimization, further driving growth and profitability.

Decade of Trust & Experience

1630+

Projects

545+

Technocrats

26+

Products and Solutions

1020+

Customers

Connect Now

Our experts would be eager to hear you.