Healthcare

Revolutionize patient care with advanced telemedicine solutions and AI-driven diagnostics.

Our Clients

Manufacturers operate with fragmented data and reactive decision-making that reduce throughput, keep bottlenecks out of view, and overburden teams. Applying AI and data in manufacturing unifies shopfloor and enterprise information into governed models that drive action. Predictive models, smart applications, and data analytics in manufacturing turn machine, quality, inventory, and energy data into clear actions across maintenance, production, and supply chain. The result is simpler workflows, higher uptime, improved Overall Equipment Effectiveness (OEE), greater throughput, better quality, and faster response to supply chain disruptions.

Softweb Solutions brings 21+ years of experience in platform strategy, solution delivery, and risk management, with proven expertise in AI manufacturing consulting services. Our team designs practical roadmaps and implements data-driven manufacturing solutions on Azure, AWS, and Databricks with edge computing and cloud manufacturing. We have delivered AI software for manufacturing companies across automotive, electronics, aerospace, healthtech, and food and beverage industries.

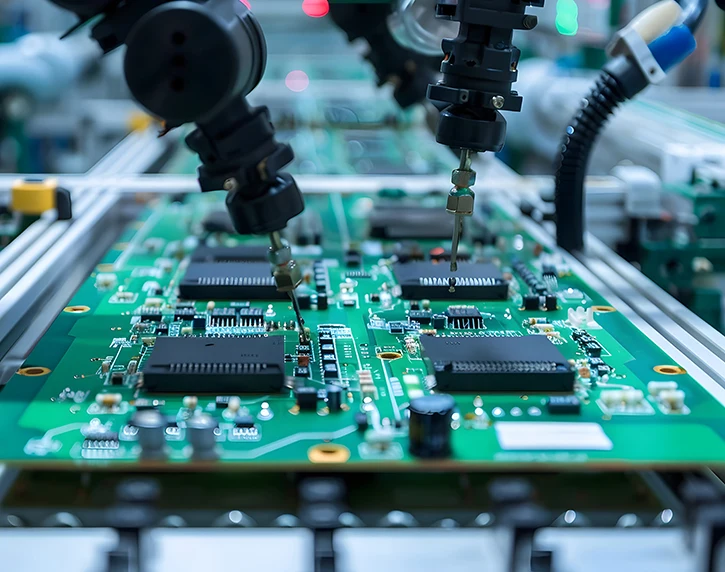

Electronics

Electronics manufacturers manage large SKU counts and rapid changeovers. We build solutions that unify device, test, and Manufacturing Execution Systems (MES) data to create shop-floor intelligence for inline inspection, demand–supply balancing, and inventory management. With real-time dashboards, guided actions, and product traceability, production, quality, and planning teams cut scrap and clear bottlenecks. With edge computing and cloud manufacturing, yield optimization and throughput improvement scale across lines without added complexity.

Machine manufacturing

Machine builders need uptime, precision, and cost control. Through sensor data analytics, our solutions predict failures, tune parameters, and surface micro-stoppages. MES integrations and role-based dashboards improve first-pass yield and shorten cycle times. As bottlenecks clear, asset performance management improves, and on-time delivery stabilizes. Clear guidance for changeovers and setups keeps the production pipeline disciplined across cells and variants.

Semiconductors

Semiconductor operations demand precision at scale. We combine inline, test, and equipment signals with AI vision to detect defects, stabilize parameters, and increase yield. MES integrations strengthen product traceability and compliance records. Digital twins let engineers trial changes safely, while edge computing speeds feedback across tools and chambers. The outcome is less downtime, higher OEE, and faster, consistent decisions across fabs and assembly.

Automotive manufacturing

Automotive programs require zero-defect quality and tight takt. We deploy vision models to verify welds, sealant, paint, and assembly presence, while forecasting aligns production with demand. By integrating MES with inventory management, operations teams can remove bottlenecks, cut scrap, and increase OEE. Energy analytics lower consumption, and role-based dashboards keep plants and partners synchronized as changes roll through body, paint, and final assembly.

Aerospace

Aerospace needs repeatability and evidence at every step. We use computer vision and inspection analytics to improve detection, while electronic travelers and unit-level serialization strengthen product traceability. Predictive models lower equipment downtime and support asset performance. With governed data and role-based dashboards, teams standardize work, pass audits faster, and run process optimization confidently across structures, systems, and MRO while maintaining workforce safety.

Healthtech and pharmaceutical

Healthtech and pharma require validation and complete traceability. We combine vision checks, electronic records, and governed data to strengthen quality. Predictive analytics monitor critical parameters and equipment health; digital twins let teams test changes safely. With MES and role-based dashboards, teams reduce deviations, protect yield, and keep audit evidence ready across labs, cleanrooms, packaging, and distribution, supporting workforce safety.

Food and beverage manufacturing

Food and beverage plants must balance speed, hygiene, and genealogy. Our system monitors OEE, flags anomalies, and inspects fill levels, seals, and labels with edge vision. Demand forecasting and inventory management reduce spoilage and stockouts. Energy analytics optimize HVAC and utilities. With MES and real-time dashboards, process optimization and traceability are maintained across batching, packaging, and distribution without slowing the production pipeline.

We train models on time-series and maintenance logs to flag failure risk early, propose service windows, and create work orders with spares. This keeps assets available, extends life, and stabilizes throughput while maintenance, production, and planning stay aligned on timing and priorities.

Our platform aggregates machine and Industrial Internet of Things (IIoT) signals into live dashboards for speed, state, and quality indicators. When thresholds cross set limits, the system triggers alerts and guided checks. As a result, teams clear micro-stoppages faster, improve OEE, and keep shifts aligned without extra tools.

Using edge vision, we inspect surface, dimensional, and assembly features in milliseconds. Detected issues trigger guided actions and log images for evidence. Teams cut scrap and rework, standardize outcomes across sites, and feed results to MES for closed-loop quality improvement.

We forecast demand by SKU and location using sales, seasonality, promotions, and external signals. Approved plans route to production, procurement, and labor with clear confidence bands. This lets planning teams balance demand and supply, reduce expedites, and maintain service levels as markets move.

Our models set safety stock and reorder points with multi-echelon logic that respects lead times, lot sizes, and shelf life. Recommendations are posted to ERP so replenishment executes cleanly, helping teams cut stockouts and excess while improving turns and freeing cash across sites.

With AI-assisted finite-capacity planning, we consider constraints, changeovers, and material availability to generate achievable schedules. Scenario comparisons reveal risks and costs. Approved plans sync to execution systems, so lines stay fed while queues, expedites, and carrying costs steadily decline.

We measure energy by asset, line, and product, detect waste patterns, and shift loads during non-critical periods and within safety and quality limits. Operations teams tune HVAC and utilities with confidence, lowering energy per unit and emissions without sacrificing speed, quality, or safety across seasons and shifts.

Analytics track building systems and environmental readings to identify and flag issues early. The system recommends work orders, parts, and timing. This helps facility teams reduce energy use, prevent failures, and maintain validated environmental conditions that protect people, products, and equipment uptime.

AI optimizes slotting, pick paths, and labor planning; vision verifies counts and labels. With WMS, ERP, and TMS in sync, teams move goods faster, reduce errors, and shorten dock-to-stock and ship cycle times, even during peak demand.

Optimization models build loads and routes with predictive ETAs and real constraints. Early alerts and suggested fixes appear when exceptions occur; confirmed plans publish to carriers. Teams cut dwell and detention, improve on-time delivery, and keep customers informed with accurate milestones.

We identify constraints and micro stoppages, then simulate changes to cycle times, parameters, and changeovers. Operators follow the required steps, and supervisors track outcomes to confirm the impact on cycle time, yield, and OEE.Plants gain higher first-pass yield, smoother flow, and measurable throughput improvement across shifts and product variants.

Role-based dashboards unify KPIs for executives, engineers, and operators with layered views from plant to asset. Comments, alerts, and assignments keep actions moving so teams compare sites, focus resources where value is highest, and maintain one trustworthy source of truth.

Computer vision and IoT track PPE, restricted zones, and ergonomics in real time. Alerts guide the next steps: pause work, clear the area, notify a supervisor. The system also records evidence for later review. This reduces incidents and close calls, and insights drive training and layout changes that protect people without slowing production.

We digitize SOP checks, approvals, and e-signatures so evidence is audit ready. Genealogy and lot tracking link processes to parts and people. Quality and operations meet standards consistently across sites and shifts while maintaining product traceability with less effort.

AI captures, classifies, and extracts data from invoices, COAs, SOPs, and QA records. Rules validate fields, then update post to ERP and QMS. Teams cut manual entry, shorten cycles, and make documents searchable so audits and investigations move faster.

We build classification, forecasting, and anomaly models that learn from time-series signals and labeled quality data. Our ML pipelines cover feature engineering, training, and drift monitoring so models stay accurate as product mix and volumes change. Engineers receive clear outputs that lift yield, cut downtime, and control cost across sites.

Analytics models unify MES, ERP, WMS, and connected-device data into governed datasets. Role-based dashboards and drill paths convert signals into actions with shared definitions. Plant managers see KPIs, engineers trace root causes, and operators follow checklists for start-up, changeover, and quality holds. This drives process optimization, improves throughput, and keeps data consistent across teams.

Using time-series and gradient boosting, we forecast demand, failures, and quality outcomes by site and SKU. Backtesting and drift checks protect accuracy. Maintenance, planning, and quality teams receive clear, timely thresholds and next steps that guide action before issues escalate into downtime, order and shipment expediting, or service-level penalties.

Integration connects devices, gateways, and test stands to secure data platforms. The ingestion layer handles translation and buffering, then streams events to analytics and AI services. APIs link to MES and maintenance tools so actions close the loop quickly with lineage, retention, and controls that satisfy governance.

Built on Microsoft Azure or your chosen cloud, the platform ingests, stores, and models plant data securely at scale with policies for privacy, cost, and residency. Operations, engineering, and finance functions use analytics, digital twins, and APIs, while monitoring and failover keep reliability high across regions.

Edge inference and streaming analytics run close to machines, so inspection, safety, and control respond instantly under tight cycle times. Managed updates and device security keep fleets current. Summaries sync to the cloud for fleet analytics and standardized reporting that give headquarters a consistent, trusted view.

Vision systems inspect defects, verify assemblies, and check barcodes and labels on the line. Optics and lighting match your environment, and inference runs at the edge. Results post to quality systems with images for evidence so teams act quickly and document outcomes for audits and customers.

RPA automates end-to-end steps across planning, purchasing, shipping, and quality administration. It removes manual data entry, duplicate reconciliations, and status updates between systems. As a result, cycle times shrink, accuracy rises, and audit trails stay intact, letting teams focus on exceptions and high-value supplier collaboration.

We build twins for assets and processes that mirror real behavior under changing loads and schedules. Engineers test scenarios, tune parameters, and predict outcomes before deployment. Digital twins sync with live data so improvements scale confidently with assumptions, versions, and evidence documented clearly for validation and audits.

Secure copilots assist engineering, quality, and operations with search, summaries, and auto- generated report drafts using governed access to enterprise data. Retrieval keeps responses grounded and current across sources. All interactions are logged and approvals are enforced to maintain compliance as adoption scales. Benefits are tracked against clear KPIs, named owners, timelines, and structured training plans.

Applications for planning, quality, scheduling, and operator guidance fit your workflows precisely. Integrations with ERP, MES, and WMS keep data consistent across teams and partners. We deliver software with a roadmap, security reviews, and multi-site rollout support. Value is realized quickly through clear training, measurement, and ownership.

Integrate processes with end-to-end digital factory solutions.

Minimize outages using predictive maintenance and real-time monitoring.

Ensure precision with automated inspection and defect detection systems.

Optimize usage with data-driven energy consumption analytics and tools.

Mitigate risks with real-time supplier performance tracking and planning.

Resolve delays with automated workflow optimization and demand-driven scheduling.

A complete guide to computer vision for quality control in manufacturing

Download a Free Copy NowAI fuses inline metrology, test, and vision data to forecast yield and spot excursions early. The system recommends setpoint and limit changes in MES that engineers review, apply, and verify. Losses are contained before they spread to downstream lots and tools.

Models learn vibration, temperature, and utilization patterns to score failure risk and propose service windows. Maintenance adjusts preventive-maintenance schedules and reserves parts against capacity. Throughput remains stable and unplanned downtime drops without disrupting takt.

Edge vision verifies welds, sealant, paint, and assembly presence at line speed while logging evidence. Guided checks and corrective actions trigger instantly, and genealogy links issues to station and time. This results in less rework and fewer field defects, with audit readiness improving.

Partner feeds, WMS, and ERP signals are merged to surface risks and propose rebalance options. Planning teams shift supply, reallocate stock, or adjust builds with confidence. Expedited orders decline and demand and supply stay aligned.

Models track energy by line and SKU, then recommend load shifts and setpoint changes. Operations apply safe adjustments and monitor impact. Costs per unit drops while speed and quality remain steady.

Asset and process twins let teams simulate scenarios, stress-test constraints, and tune parameters before rollout. Approved settings deploy and stay synced with live data. Improvements are made after deployment across shifts and sites.

OEE and loss trees are standardized with traceable links to actions and owners. Leaders and supervisors review gaps, assign steps, and track closure. Issues are resolved faster and a single, trusted view is maintained across lines.

True cycle times, queues, and changeovers are modeled to generate realistic schedules. Variances trigger automatic adjustments and prompt notifications to execution. Flow stays stable and impacts are communicated quickly.

Backed by 21 years of software expertise and proven experience in AI and analytics delivery

A team of 120+ AI and data experts experienced in manufacturing use cases

Certified on Azure, AWS, and Databricks for scalable, secure cloud manufacturing

Deep skills in machine learning, computer vision, digital twins, and data engineering

Proven MES/ERP/WMS integration and connected devices experience across plants and regions

Track record building IoT products and running multi-plant deployments with built in security and governance

Revolutionize patient care with advanced telemedicine solutions and AI-driven diagnostics.

Optimize network performance and data security with cloud-native infrastructure and edge computing.

Drive sustainable energy management using predictive analytics and smart grid technology.

Modernize financial operations with AI-powered risk analytics and fraud detection.

With AI and digital automations take your organization to next level.

Enhance customer engagement through personalized shopping experiences and omnichannel integration.

AI in the manufacturing industry is used for process optimization and predictive maintenance. It is also used for automated visual inspection, energy analytics, and real-time dashboards that raise visibility and speed decisions. It unifies data analytics in manufacturing to deliver shop floor intelligence and improve Overall Equipment Effectiveness (OEE).

AI is not taking over manufacturing; it is augmenting industrial automation by assisting people with faster insights, safer workflows, and repeatable quality. It moves actions from reactive to proactive and supports digital manufacturing without replacing human judgment.

Key AI applications in manufacturing include:

Generative AI in manufacturing is used to draft SOPs and reports, assist root-cause analysis, summarize compliance documentation, and provide copilots for engineering and operations. It speeds knowledge access while respecting governance and role-based permissions.

AI agents for manufacturing are task-focused assistants that read governed data and execute steps like creating work orders, summarizing loss trees, or preparing audit packs. They integrate with MES, ERP, and QMS through secure APIs and maintain an auditable trail.

Data-driven manufacturing optimization with AI is done by selecting a target KPI, building clean pipelines from connected devices and enterprise systems, training and validating models, embedding insights into workflows, and monitoring model drift. The outcome is measurable throughput improvement and downtime reduction.

AI is transforming the factory floor by turning noisy signals into clear actions, automating inspection, stabilizing parameters, and alerting teams before failures. The result is factory automation that delivers consistent quality, yield optimization, and safer operations.

AI and data analytics improve manufacturing efficiency by revealing hidden losses, balancing lines, guiding maintenance, and driving scrap and waste reduction. They provide process optimization that maintains speed while lowering energy consumption and costs.

Manufacturing processes that can be automated with AI include visual inspection, parameter checks, scheduling and sequencing, document processing, pick-path planning, and exception handling in logistics. These automations reduce manual effort and cycle time.

Industries that benefit most include automotive, electronics, semiconductors, aerospace, medical devices, textiles, and food and beverage. These sectors gain from AI in manufacturing solutions such as data-driven manufacturing solutions and smart manufacturing with AI.

AI can integrate with ERP, MES, and SCM via APIs, event streams, and governed data models. This is how AI software for manufacturing companies delivers end-to-end visibility, consistent data, and faster decisions without disrupting current tools.

Build smart factories with AI to cut waste and increase OEE

Tell us your requirement and we’ll map a clear path, timeline, and expected impact