AI and data solutions for the supply chain companies

Our AI-powered solutions predict demand, optimize inventory, and prevent costly delays with complete operational control

Optimize your supply chainOur Clients

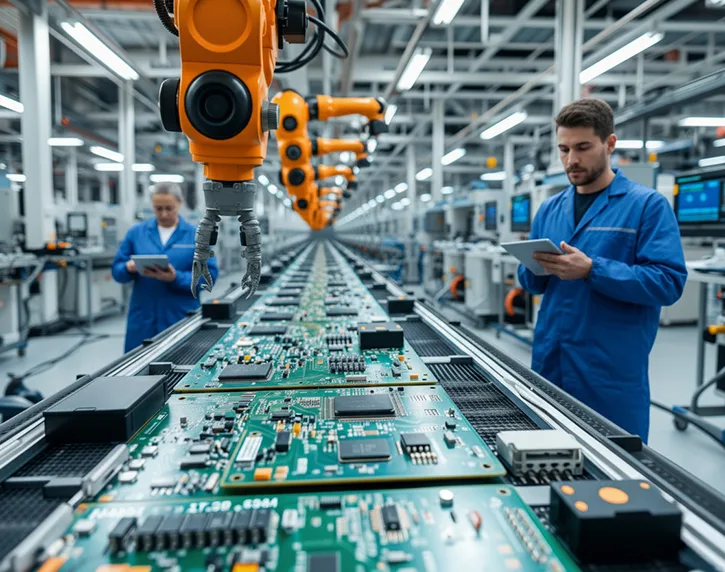

Our AI solutions turn complex supply chain data into actionable insights, helping you reduce waste, improve efficiency, and stay ahead of demand fluctuations. We integrate machine learning, computer vision, IoT sensors, and predictive analytics into your existing systems, creating unified workflows that turn data into immediate action across procurement, logistics, and distribution.

This provides complete visibility and control that enables faster decision-making, reduces waste, and improves customer satisfaction. Our AI-powered supply chain solutions have helped companies across retail, manufacturing, pharmaceuticals, and logistics achieve 30% cost reductions while eliminating stockouts.

Implement Just-In-Time (JIT) manufacturing and lean production methods with our AI-powered scheduling systems that analyze demand patterns and optimize production runs. Our solutions constantly modify production schedules in response to current demands, minimizing waste and maximizing the utilization of resources. This creates flexible and responsive production that enhances efficiency, minimizes costs, and maintains consistent product quality in dynamic market conditions.

Optimize global transportation with our AI software that maps out optimal routes, automates freight consolidation, and delivers real-time shipment tracking on all carriers. Our data analytics solution in supply chain continuously monitors traffic, weather, and delivery windows to adjust routes dynamically. It helps you optimize logistics operations by reducing transit time, minimizing fuel usage, and enhancing last-mile delivery effectiveness.

Use our predictive analytics platform to forecast customer demand with precision by analyzing historical sales, market trends, seasonal patterns, and external factors. Our smart supply chain with AI technology generates accurate forecasts and automatically adjusts safety stock levels. Therefore, it helps you build adaptive, customer-focused supply chain that also consistently meets demand, optimizes excess inventory, and improves service levels.

Design your best distribution plans with our AI technology that computes Economic Order Quantity (EOQ) and develops dynamic routes based on current conditions. Our system allocates inventory throughout your distribution network automatically so that products are placed as close as possible to demand. Such arrangement guarantees timely delivery, eliminates distribution costs, and allows effective global coverage with appropriately balanced inventory levels.

Automate warehouse operations with technologies like Automated Storage and Retrieval Systems (ASRS) and AI-driven inventory optimization that direct product placement and picking paths. Our computer vision systems track product movement in real-time and optimize storage layouts continuously. Automation accelerates goods movement, decreases holding costs, and enables smooth order fulfillment with complete visibility into warehouse operations.

Streamline end-to-end supply chain operations with our integrated platform that implements total quality management and process automation across all functions. Our solution tracks key performance metrics, detect bottlenecks, and recommend optimizations. The integration of AI and data analytics maximize operational performance, reduces interruptions, and boosts profitability through strategic planning, effective execution, and data-driven performance measurement.

Retail and e-commerce

Our data and AI solutions help retail and e-commerce companies with stock levels, customer demand forecasting, and optimize fulfillment operations.

With intelligent supply chain technology, we reduce stockouts, excess inventory, and delivery times. Our solution monitor consumer behavior patterns and seasonal trends to help you stock the right products at the right time.

From online marketplaces to physical stores, we help retailers maintain their competitive edge and adapt quickly to changing customer expectations.

FMCG (Fast-Moving Consumer Goods)

We help FMCG companies with demand forecasting, production planning, and distribution optimization to handle the complexity of their multi-faceted operations.

We help them manage intricate product portfolios, minimizing waste from perishable products, and getting products on shelves when consumers need them.

Our solutions manage high-volume and quick-turnover operations efficiently. With tight margins and short shelf lives, FMCG companies need precise coordination that our AI systems deliver consistently.

Automotive

Automotive manufacturing requires precise coordination between dealers, manufacturers, and suppliers.

Our logistics and supply chain AI software facilitates the management of intricate parts inventory, just-in-time delivery coordination, and quality tracking throughout the supply chain.

We maximize production schedules and eliminate expensive manufacturing delays. Our solutions also help automotive companies adapt to changing demand for electric vehicles and new mobility services.

Electronics

Electronics supply chains deal with component shortages, rapid product cycles, and global sourcing. Our data-driven supply chain planning optimizes managing component inventory, tracking supplier performance, and projecting product releases.

We use AI to forecast the availability of components and suggest substitute source strategies.

With technology evolving rapidly, electronics companies require responsive supply chains that can shift instantly when new opportunities emerge.

Pharmaceuticals and life sciences

Pharmaceutical supply chains need strict compliance, temperature tracking, and traceability. Our smart supply chain powered by AI ensures product quality, date expiration management, and regulatory compliance.

We assist in the tracking of medicines from manufacturing to patient distribution while minimizing wastage and guaranteeing availability.

Patient safety depends on reliable supply chains, making our precision-focused approach essential for healthcare outcomes.

Food and beverage

Food and beverage businesses use our AI solutions in supply chain management to handle perishable inventory, improve cold chain transportation, and maintain food safety.

We reduce spoilage, handle fluctuations in seasonal demand, and synchronize intricate distribution networks. Our solutions trace products from farm to plate.

Fresh products require perfect timing and temperature control, which our monitoring systems provide throughout the entire supply journey.

Industrial and manufacturing supply chains

Our supply chain analytics solutions help industrial manufacturers with raw material purchasing, production scheduling, and distribution of finished goods.

We assist in supplier network complexity management, limiting production downtime, and enhancing on-time delivery performance. Our AI tools align several manufacturing locations and distribution facilities.

We facilitate smooth coordination between equipment, materials, and logistics to ensure profitability and customer commitment.

Logistics

Logistics operators leverage our data and AI solutions to optimize delivery performance, fleet management, and route planning across their supply chain business.

We help reduce fuel costs, improve driver productivity, and customer satisfaction with better delivery tracking and communication. We offer last-mile delivery optimization and warehouse automation.

With expanding e-commerce, logistics businesses require intelligent technology to manage growing volumes while maintaining service quality and managing costs.

10+

Years in AI and data solutions

1630+

Projects delivered

50+

Fortune customers

545+

Technology professionals

Our supply chain AI solutions utilize intelligent algorithms to forecast demand with precision. It will help you analyze previous sales, seasonal patterns, weather conditions, and local events to predict the products you'll require and when. This helps you stock the right goods at the right moment to increase profitability.

Our intelligent supply chain solution segregates inventory into different categories and makes custom plans for each product type. We help you find the balance between having enough stock to meet demand without wasting money on excess inventory. Our system tracks what's selling, what's not selling, and adjusts your orders accordingly.

Our artificial intelligence solution for supply chain and logistics determines optimal routes for your drivers daily. The system takes traffic, weather, delivery time windows, and truck capacity into account to develop routes that reduce fuel consumption and save time. This reduces delivery expenses by 15-25% and ensures consistent deliveries.

Our AI supply chain solutions help you detect issues before they strike. It will monitor your suppliers' financials, their shipping performance, and potential signs of trouble. When issues arise, you receive notifications along with recommended alternative suppliers. We streamline the processes of requesting a quote and enrolling new suppliers.

Our data-driven supply chain optimization streamlines the process from order creation to approval. The system understands who needs to approve what, based on order size, department, and site. Approvers can review and approve orders on their mobile phones. Orders that used to take days to process now take just hours with our AI and data solution.

Our supply chain AI and data solutions streamline the flow of products through your warehouse from receiving to shipping. The system directs the most efficient routes to pick orders, monitors inventory in real-time, and forecasts product requirements. Intelligent warehouses ship orders faster than traditional warehouses while minimizing errors.

Our control tower provides real-time visibility into inventory levels, supplier performance, and potential issues throughout your locations. You can anticipate issues and prevent them in time. The dashboard shows you precisely what you need to work on and recommends what to do about it.

Our supply chain AI solutions help you monitor and enhance both environmental and social footprints. We route deliveries more efficiently to lower fuel costs, reduce waste across your operations, and track suppliers for equitable labor practices. The platform enables you to achieve sustainability objectives while saving money.

Optimize your supply chain operations today!

Schedule a call with our expertsMachine learning enables your supply chain to learn from historical information and anticipate future requirements without the need for constant programming. Our data and AI in supply chain offerings leverage these intelligent algorithms to predict demand, anticipate equipment failure, and adjust inventory levels automatically.

Our supply chain data analytics solution turns raw data into simple-to-interpret charts and dashboards that reveal precisely what’s going on in your operations. You can see trends, find issues, and measure performance immediately, allowing managers to quickly and confidently make decisions.

Our smart supply chain with AI technology analyzes supplier performance patterns, demand fluctuations, and market conditions to notify you about advancing disruptions. This enables you to respond ahead of time and find alternative suppliers, reschedule stock, or shift production schedules in time.

Edge analytics processes data where it’s being created – in trucks, warehouses, and distribution facilities. Our logistics and supply chain AI software provides real-time visibility into vehicle operation, cargo status, and delivery status. Drivers get real-time route direction, and managers can track shipments remotely.

Computer vision employs cameras and artificial intelligence to “look” at what is happening in your warehouse. Our AI supply chain consulting services apply vision systems that count inventory automatically, inspect product quality, and direct workers to the appropriate locations. This eliminates mistakes of manual counting and accelerates order processing.

Our data-driven supply chain optimization leverages RPA to mechanically process purchase orders, update stock systems, and issue confirmations to suppliers automatically. It avoids human mistakes and processes orders 24/7 without pause, making your operations considerably faster and more consistent.

A digital twin builds a virtual replica of your entire network of suppliers that mirrors what occurs in the real world. Our supply chain solutions based on AI utilize the virtual representation to simulate different scenarios, optimize designs, and forecast what changes will happen in your business.

Generative AI develops various “what-if” scenarios to assist you in planning for various business situations such as supply shortfalls, spikes in demand, or economic shifts. Our data and AI solution for supply chain industry produce comprehensive plans for various scenarios, illustrating the optimum response to market fluctuations.

Reduce waste with intelligent demand forecasting and stock management.

Balance operations using advanced demand analytics and planning solutions.

Ensure reliability with automated supplier performance analysis and monitoring.

Enable transparency with integrated tracking across supply chain touchpoints.

Mitigate risks through predictive cost analysis and optimization tools.

Streamline logistics through real-time tracking and proactive alerts.

AI improves efficiency by automating routine tasks, predicting demand, optimizing logistics, and reducing manual errors. With AI in supply chain solutions, businesses achieve faster decision-making, lower costs, and smoother operations.

Data analytics in supply chain is used for demand forecasting, inventory planning, supplier performance tracking, logistics optimization, and risk prediction. It helps companies uncover patterns, improve planning, and make better data-driven decisions.

AI models analyze sales history, market trends, and external factors like weather or local events to forecast demand more accurately. This enables data-driven supply chain optimization, ensuring the right products are stocked at the right time while reducing overstock and stockouts.

Yes. With tools like AI-powered control towers and predictive risk analysis, businesses gain end-to-end visibility into their supply chain. Integrating AI and data in supply chain improve supplier monitoring, detect risks early, and provide insights for proactive action.

Generative AI simulates “what-if” scenarios such as demand surges, supplier failures, or transportation delays. It helps leaders evaluate multiple strategies quickly, making supply chain planning smarter and more resilient.

Absolutely. AI software for logistics and supply chain can be integrated with ERP, SCM, and TMS platforms to enhance automation, improve data visibility, and deliver actionable insights without disrupting existing workflows.

Industries like retail, e-commerce, manufacturing, logistics, CPG, automotive, and healthcare benefit greatly. Our AI supply chain consulting services are designed to meet industry-specific needs, from demand forecasting to last-mile delivery.

AI helps optimize truckloads, delivery routes, and energy usage, reducing waste and emissions. With AI-powered smart supply chain, businesses achieve operational efficiency while meeting environmental and compliance goals.

We provide solutions such as data integration, real-time dashboards, advanced analytics, predictive modeling, and data-driven supply chain optimization. These solutions ensure clean, reliable data for smarter planning and execution.

Our offerings include demand forecasting, inventory optimization, route planning, supplier risk management, warehouse automation, AI-driven control towers, and sustainability monitoring. These AI in supply chain solutions help tackle common challenges like delays, inefficiency, and risks.

By combining AI and data in supply chain, we help your business automate operations, cut costs, and respond quickly to market changes. Our services provide scalability, agility, and insights that support long-term growth and competitive advantage.

Strengthen your logistics operations with AI and data-driven optimization

Our AI-powered supply chain solutions accelerate business growth while reducing risks and inefficiencies